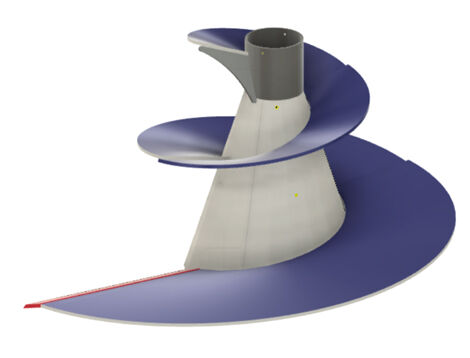

Vertical Feed Mixer Wagons

Common to many Original Equipment Manufacturers (OEM's) designs are large, lower helix lead-edge, with Outer Diameters of up to 2,700mm that have to be highly-accurate, with tight-fitting tolerances on the lead-edge; this enables the blade to sweep material without waste off the wagon floor. This fact, together with being able to form these helices with an aggressive perimeter taper in their final cut form, allows Helix Flight Forming Technology to lead the way in this highly-specialist, and demanding, field of helix forming manufacturing. Our Blank Cut Design Management (BCDM) software makes a simple task of what once (and to some, still is), an exceptionally tough task to achieve with any certainty of success.

Remember – Helix Flight's Technology has far less wastage, when alternative machines must also add tags into the plate to help create the perimeter taper; and then additional time has to be spent to re-cut the plate, adding considerable costs due to the extra time needed for the further grinding and polishing necessary to get the taper finished to the required specifications. This is known to be difficult, and costly work which is also associated with a lot of material wastage using other machines, or labour intensive ways to achieve a similar outcome... invariably, never with the quality or as accurately as a Helix Flight Forming Machine!

Helix Flight Technology enables complete versatility when creating a perimeter tapered helix, with NO limitation on the kind of shaft used: Conical, Square, Hexagonal, Stepped, etc. Helices on a Helix Flight Machine are able to be cut and formed flawlessly, with the utmost precision to fit the required shaft perfectly ...first time ...every time!

Click Here to View our Machines

Click Here to View our Machines

English

English English

English Japanese

Japanese Spanish

Spanish Italian

Italian Portuguese

Portuguese