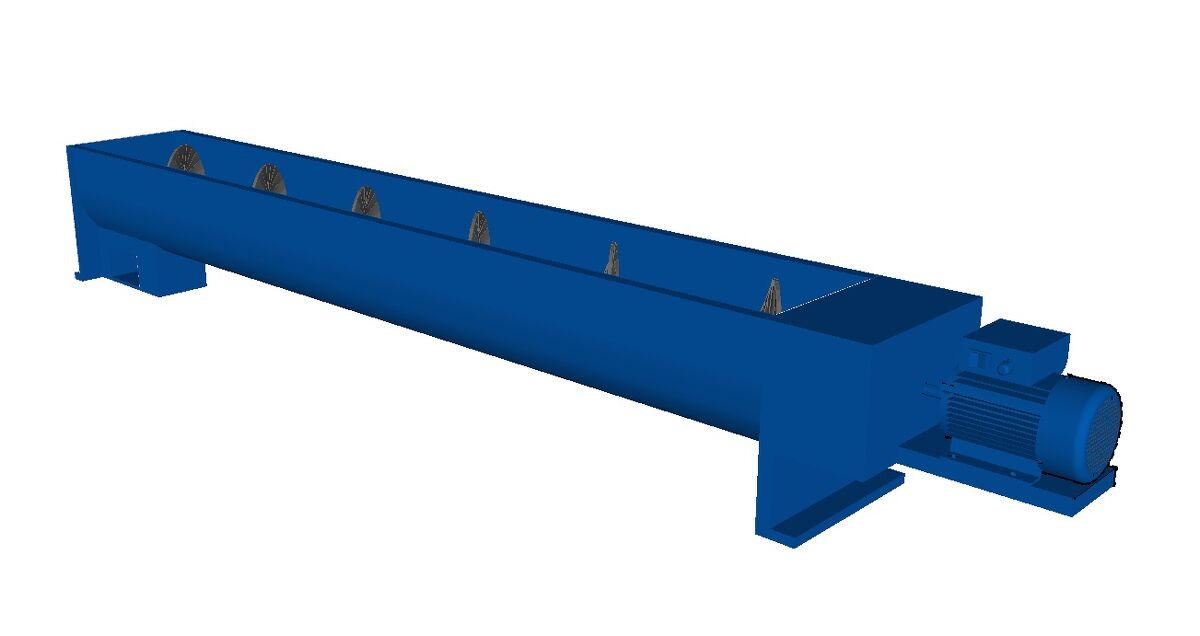

Screw Conveyors

Screw conveyors are used to convey materials from point A, to point B, whether that is from tiny, stainless steel augers for the pharmaceutical industry; or, super-heavy-duty conveyors used for moving course, abrasive and heavy industrial materials and everything in-between, screw conveyors are functional across a vast array of industries.

Giving complete flexibility over the critical variables, including: The Diameter of the plate, Shaft size, Pitch, Thickness, and Grade of material used, (Mild Carbon Steel, Stainless Steel, High Tensile Steel, Abrasion Resistant Plates, Chromium Carbide sandwich plates, etc.) the owner of a Helix Flight Forming Machine has the freedom and ability to design the most effective and efficient solutions for almost any given project.

Flexibility

Our machine and software allow total flexibility in the design of pitch, size, notches, legs, tapers, left or right-hand Flights. Square internal diameters, or square perimeters, are now an option with the capability to handle Outside Diameters of 200mm to 1,350mm, in up to 32mm blank thickness.

High Speed

Helix Flight forming speeds varies relative to the size of the Flight being formed, this can be from under 1 minute for simple flights, up to 3 minutes (or slightly more) for production runs of large, one-metre diameter, 25mm thick helices, with a 150mm pitch that is to fit-up onto a 273mm shaft.

High Quality

Manufacturing is possible with a flush-fit across Helix Flight's joins and the “click-tight” fit-up of the produced Helix Flights to the central shaft.

Uniform... True Form!

Helices with a consistent pitch angle means that less wear-points are created and minimises unnecessary damage to the face of the Helix. Also, there is reduced wear on motor drives and bearings that are being used in the conveyor.

Training

Operators can go from having no experience to being fully-productive with only 2 to 3 days of straightforward instruction. This means that an operator will be able to predict the forming sequence for new Helix designs, and because of this ability they can also help in the future development of specialist Helices for unique manufacturing needs.

English

English English

English Japanese

Japanese Spanish

Spanish Italian

Italian Portuguese

Portuguese