True Form Helix Manufacturing...

Machines...

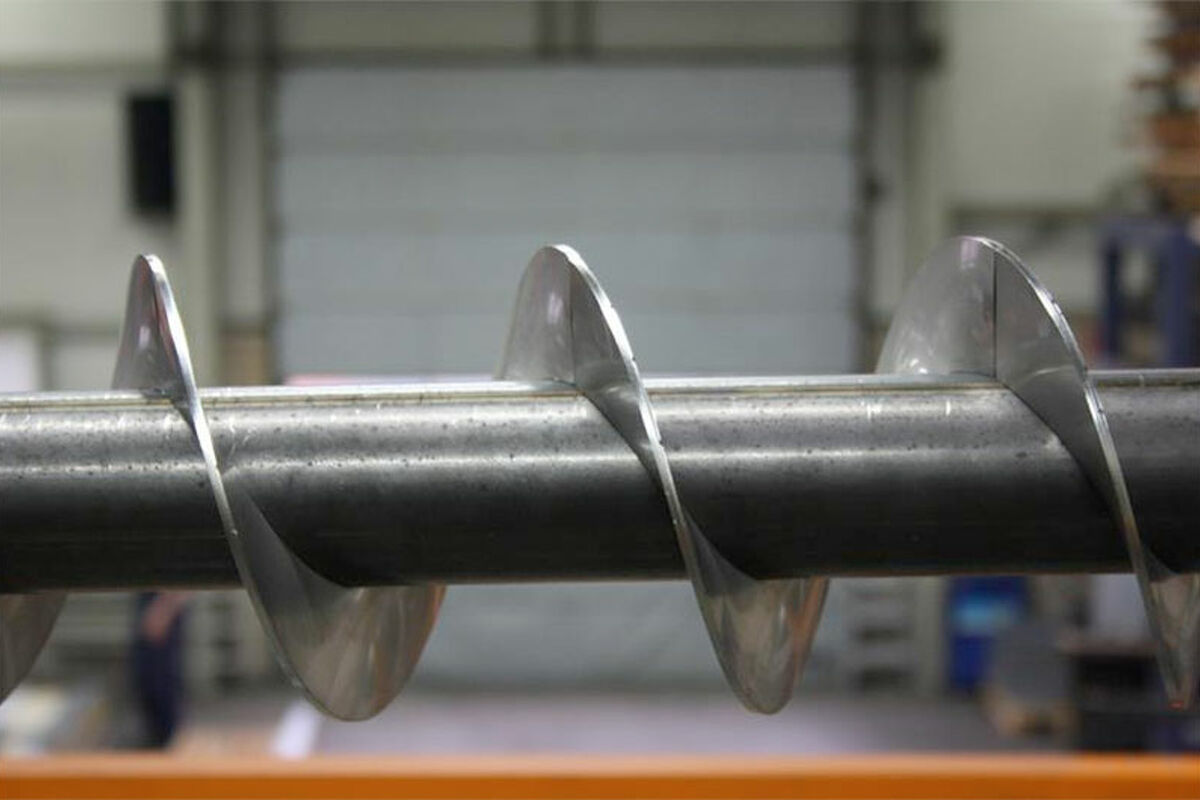

Helix Flight Manufacturing Machines Limited (Helix Flight), specialise in making machines that produce True Form Sectional Helices (industrially known as "Flights"). Helix Flight are now renowned for introducing this global innovation to a niche, highly-specialist sector of machine manufacturing.

Helix Screw "Flights" are used across many applications, such as Augers, Screw Conveyors, Agitators, Marine Anchors, Screw Piles, Screw Presses, Turbines and a multitude of other practical, commonly used Screw-Flighted products.

With over 20+ years of expertise in the Flighting industry and with an extensive global presence, our world-leading and Award-Wining technology offers versatile, State-of-the-Art machines, to produce sectional helices with different specifications ranging from 2 inches (50.8mm) up to 157 inches (4,000mm) Outer Diameter (OD).

Helix Flight provides inclusive training with our user-friendly design software, this helps to ensure the quick and effective uptake of the production process to safely, and swiftly, manufacture precision Helix Flights which are reliably accurate for the numerous applications associated with the many industries that use them around the globe.

Our market-leading technology delivers long-term, defensible, competitive advantages in Sectional Helix Flight manufacturing.

Safety...

The highest Safety. Eliminating many of the primary causes of injury that were identified by an industry incident survey which covered the last 30 years.

Training...

This only takes 2 days for commissioning the machine, a full safety induction and comprehensive operator training to completion within 3 days.

Speed...

Taking as little as 25 seconds per Helix formed for straightforward items.

True Form...

True Form helices ensure that the flange is always perpendicular (90 degrees) to the shaft, keeping the internal edge parallel to the shaft, this ensures an accurate fit-up to the shaft for a perfect job.

Adjustability...

Ultra-adjust-ability and flexibility are the primary features of all Helix Flight machines. Each machine is manufactured to offer a broad range of options in the production of a formed helix, each with an extremely wide range of sizes and differing specifications. Also, the machines are designed for a swift set-up between jobs, and features that adjust within seconds to allow for the variable changes experienced with the different types of Steel, Hardox and Abrasive Resistant material blanks.

Whole-of-Life Machine Costs...

The expected service life of a Helix Flight machine is 25 years, or 1,000,000 Helices manufactured, with planned low-maintenance.

NO high tensile raised blades which mark helices and compromise safety

NO helix grab kinks and no risk of pitch and fit-up issues due to post forming stress release problems

NO tags and cut-aways required for forming tapered, notched, or legged, helices

NO time-wasting manual set-up adjustments, and NO throw-away items while dialling-in on precise settings

NO Shims or Packers required for forming Abrasion Resistant materials

Machines

Global Locations

Continents

Sectional Helices produced on Helix Flight Machines

English

English English

English Japanese

Japanese Spanish

Spanish Italian

Italian Portuguese

Portuguese